SeaTile

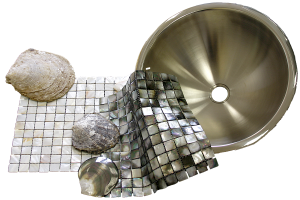

SeaTile® A unique collection of natural shell tiles and man-made composition tiles which incorporate crushed shell and other aggregates. The natural shell tile collections… ceramic back laminates, polished mosaic shell, seamless shell and capiz shell are designed for interior use and the specialty gem series and other composition tiles are designed for both interior and exterior applications. Each collection is designed as a complement to our brand SeaStone® These brands together are designed to harmonize design and may be incorporated in both residential or commercial designs.

Due to the natural variance of the raw materials used, SeaTile® products can be expected to differ from sample to actual product and may differ piece to piece.

The Complete SeaTile Collection

- Complete Collection

- Ceramic Back & Laminates

- Capiz Shell & Medallions

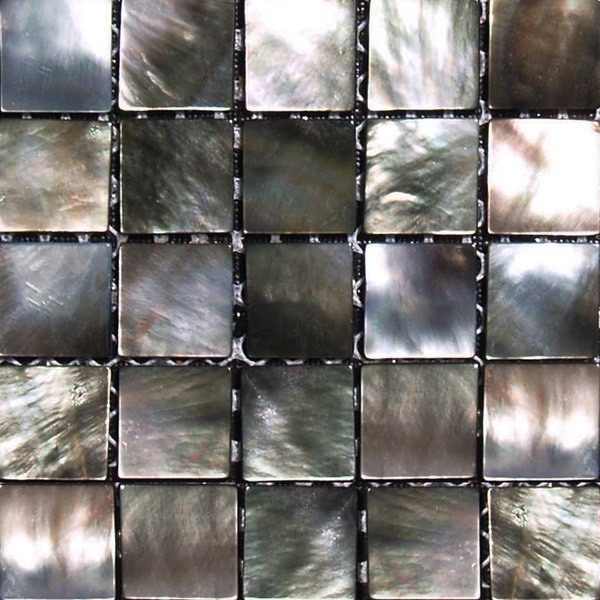

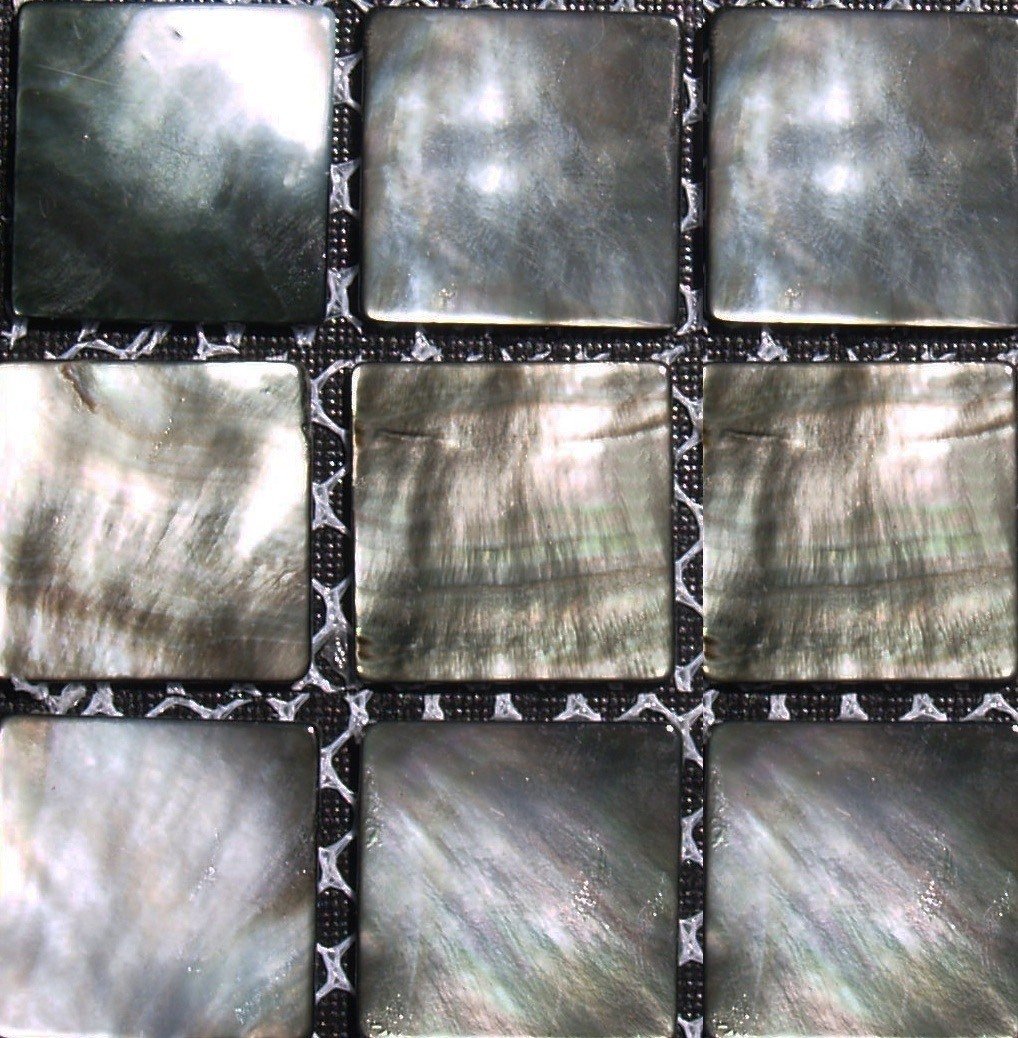

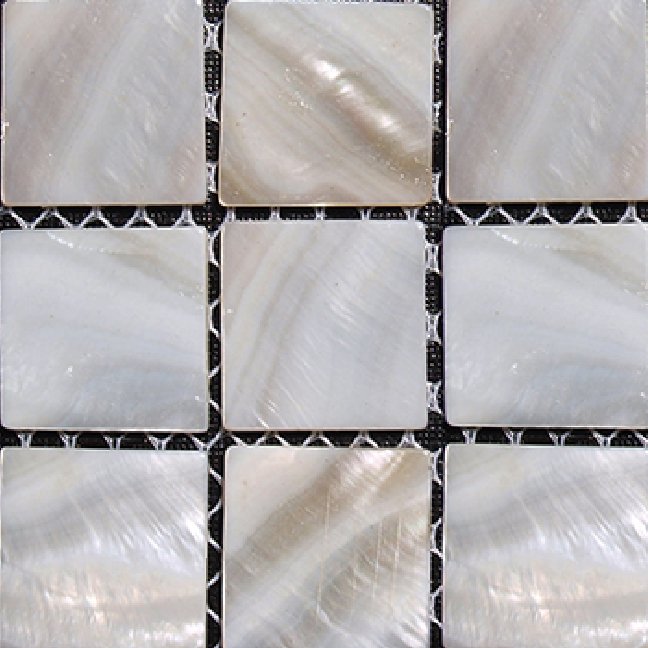

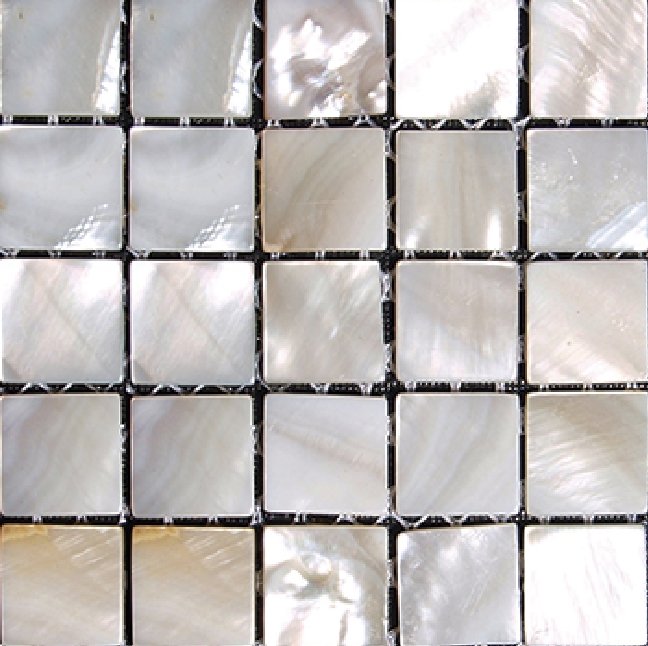

- Polished Natural Shell Mosaic Tile

- Seamless Panel Shell Mosaics

- Specialty Gem

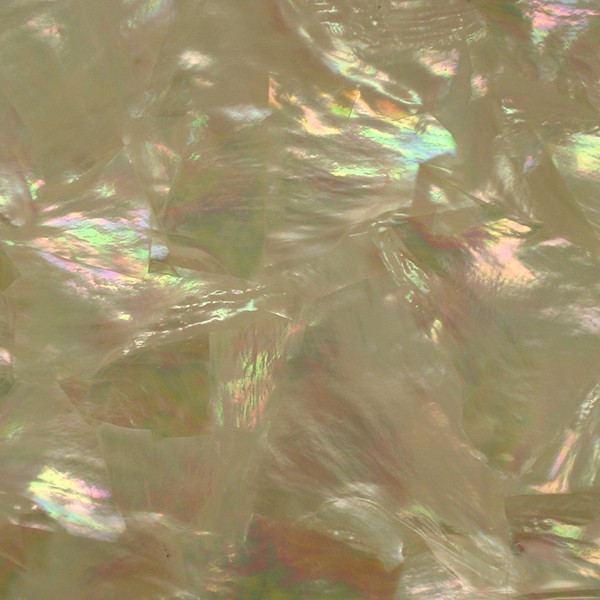

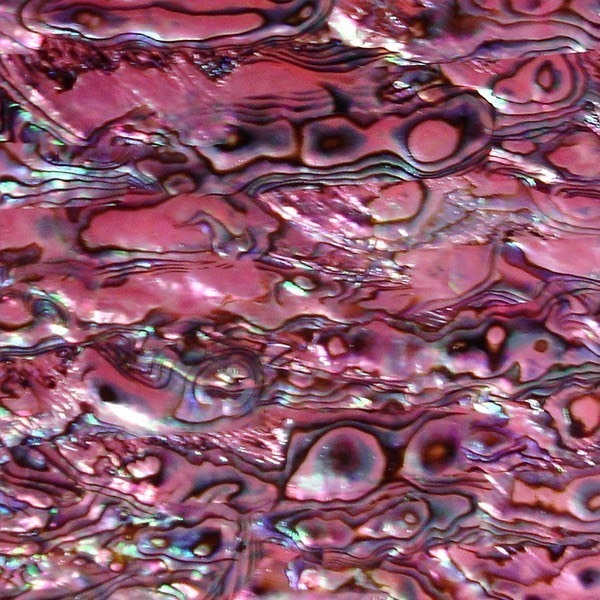

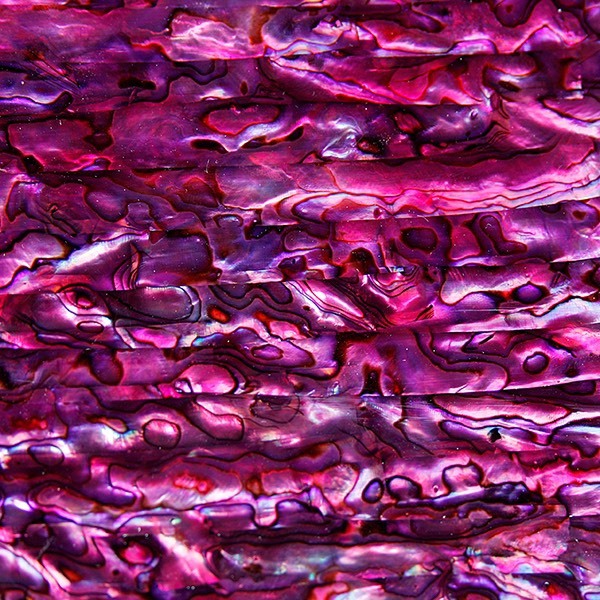

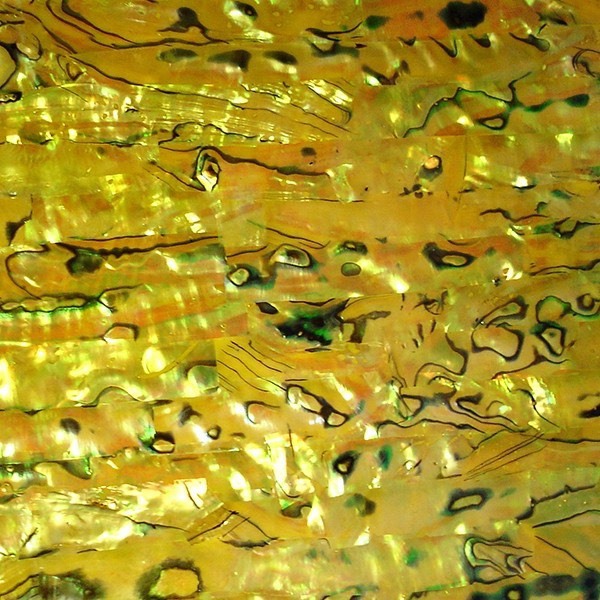

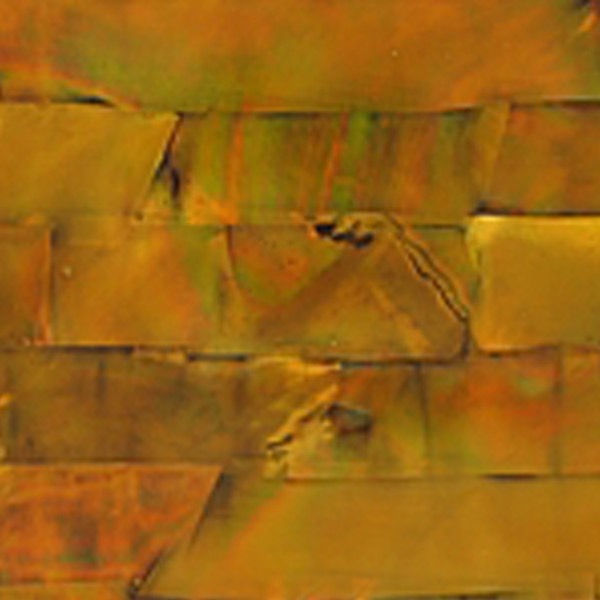

SeaTile Ceramic Back and Laminate Tiles are created by a proprietary process that uniquely applies the gem grade shell laminate to unglazed ceramic tile. The shell laminate skins are uniquely prepared with a thin coating on the reverse to enhance their natural or tint colorations. Both the tiles and laminates are then coated with a high gloss, heat resistant two-pack polyurethane for protection and stain resistance. Raw shell laminates are available in 4 (four) natural colors and uncoated for translucent effect under artificial or natural light.

Colors + Finishes

SeaTile ceramic back tiles and shell laminates are available in 4 (four) natural colors and a variety of color tints. SeaTiles are offered in two distinct thicknesses: 1/4” (6mm) mounted on bisque back and 1/64” (0.3mm) for skin laminate.

Raw shell laminates are available in 4 (four) natural colors and uncoated for translucent effect under artificial or natural light.

Natural shell colorations may vary from piece to piece which enhances the natural beauty of the product.

Sizes

SeaTile ceramic back tiles are available in seven standard sizes, 2”x 2” (50*50mm), 4”x 4” (100*100mm), 8”x 1” (200*25mm), 8”x 2” (200*50mm), and 8”x 4” (200*100mm) in solid tile and two mosaic insert designs 8”x 1-3/8” (200*32mm) & 7-1/2” x 2” (190*51mm). SeaTile laminate veneers are available in three standard sizes, 9-1/2”x 5-1/5” (230*130mm), 8”x 8” (200*200mm) & 12”x 12” (300*300mm). Raw shell laminate available in 9-1/2” x 5-1/2” (230*130mm) only. (All sizes nominal)

Applications

SeaTile products offer limitless possibilities for use in design:

Vertical tile accents, Wall covering, Cabinetry Veneers, Lighting, Paneling, Yachts, Aircraft, Tour Buses, Fishing Lures, Guitars, Surf Boards, Decorative Hardware, Crafts, Signage.

Installation + Maintenance

Ceramic Back Tiles may be installed using standard installation for ceramic tile and are recommended for vertical installations. Shell laminates are offered with or without self-adhesive backing or can be set with standard contact adhesives. Consult your tile or wall covering professional according to design application.

Use only non abrasive and non-corrosive cleaning agents such as soap and water.

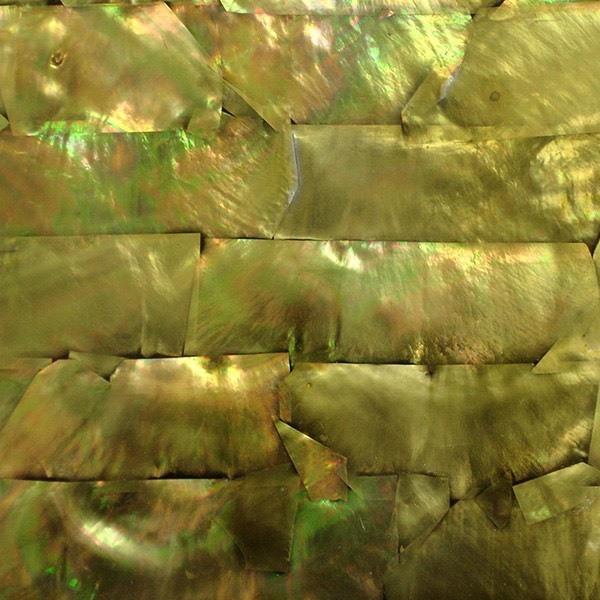

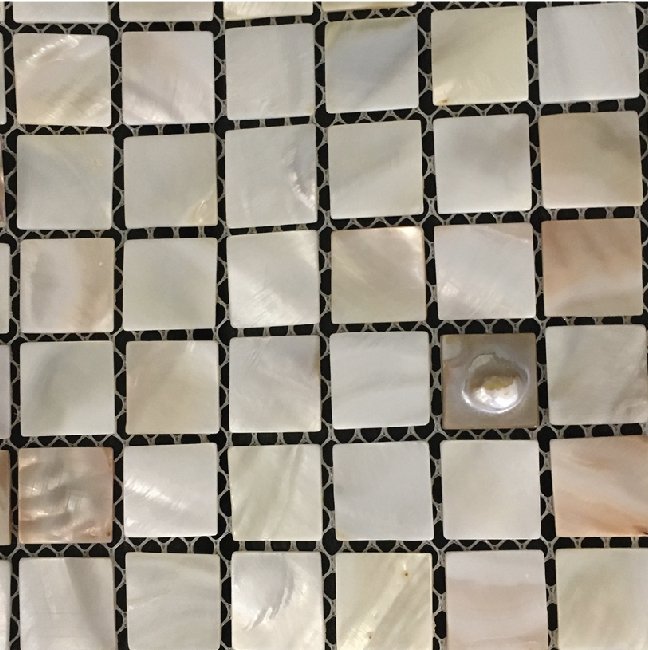

SeaTile Capiz: Genuine individual Capiz shells are placed on thin standard 18”x 18”x 1/16” or 12”x 24”x 1/16” panels, with a fire rated coating to protect the surface. Product is also available in a number of geometric pressed patterns in 18”x 18”x 1/2”, used singularly or as a repeat by design.

Colors + Finishes

Natural White and gold are standard colors. Capiz tiles are also available in Abalone and Black wash colors. These tiles are available in Standard pattern (no scoring) or scored to replicate smaller tiles. Natural shell may vary from piece to piece, which enhances the beauty of the product.

Backing

Standard tiles are mounted on a fabric mesh backing. Geometric pressed products are mounted on 1/2” fire rated MDF backing.

Applications

Capiz products offer limitless possibilities for use in design: Vertical tile accents, Wall covering, Cabinetry Veneers, Lighting, Paneling, Yachts, Aircraft, Tour Buses, Decorative Hardware and accessories.

Installation + Maintenance

Normal setting material suitable for wall covering surfaces. Product is recommended for interior, commercial & residential vertical and ceiling installations. Tiles may be cut to various sizes (consult your wall covering professional) according to design application. Thin scored product allows for minor flexibility for curved walls.

Use only non abrasive and non-corrosive cleaning agents such as soap and water.

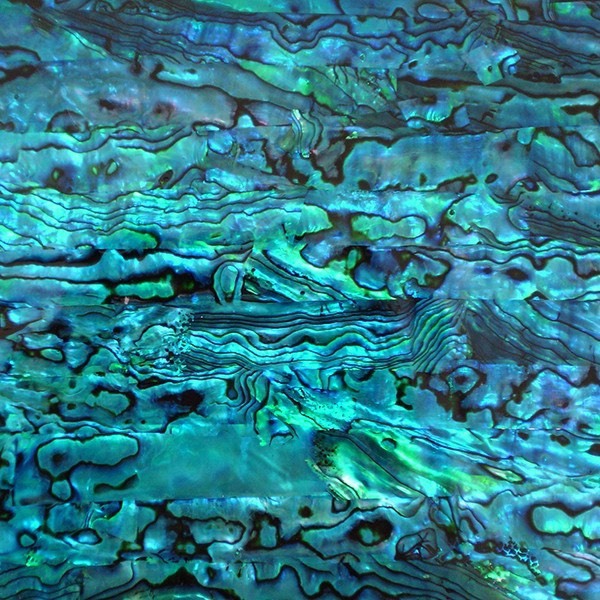

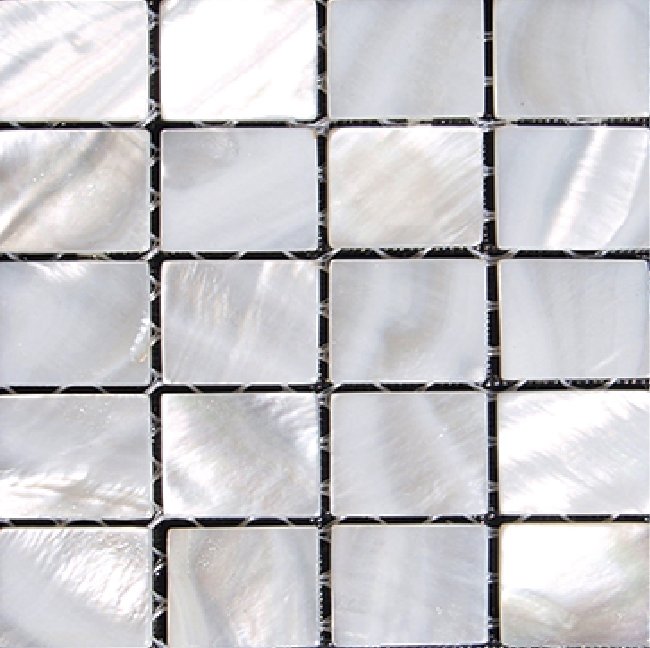

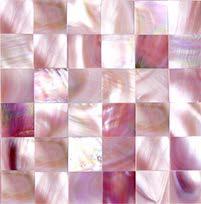

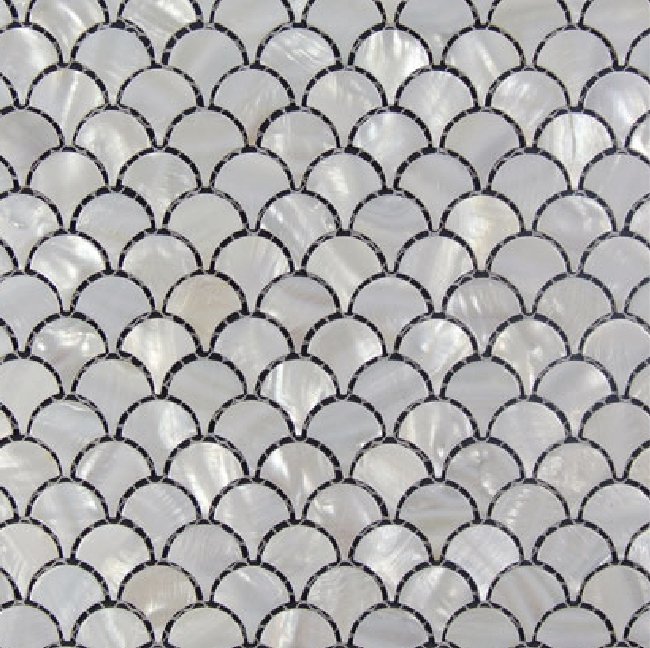

Genuine Polished shell mosaic tiles are buff polished and back mounted on mesh backing in standard size tiles that are 12” x 12” x 1/64th” (300*300* 1.2mm). The natural shell mosaic is factory applied to the mesh in various mosaic sizes 5/8” – 1” x 1” (15mm – 25mm) joint size spacing is 1/16”. All sizes shown are nominal.

Sizes

SeaTile Genuine Polished Shell Mesh Mosaic tile come in standard size tiles that are 12” x 12” x 1/16th” (300*300* 1.2mm) and come in various mosaic sizes and shapes including random patterns – 5/8” – 1” x 1” (15*25mm) joint size spacing is 1/16”. All sizes shown SeaTile products offer limitless possibilities for use in design: Vertical tile accents, Wall covering, Cabinetry Veneers, Vanity Tops, Lighting, Paneling, Yachts, Aircraft, Tour Buses, Fishing Lures, Decorative Accessories, Crafts, Signage.

Installation + Maintenance

Products may be installed using standard installation for ceramic tile and are recommended for vertical installations and Vanity tops. Use only non abrasive and non-corrosive cleaning agents such as soap and water.

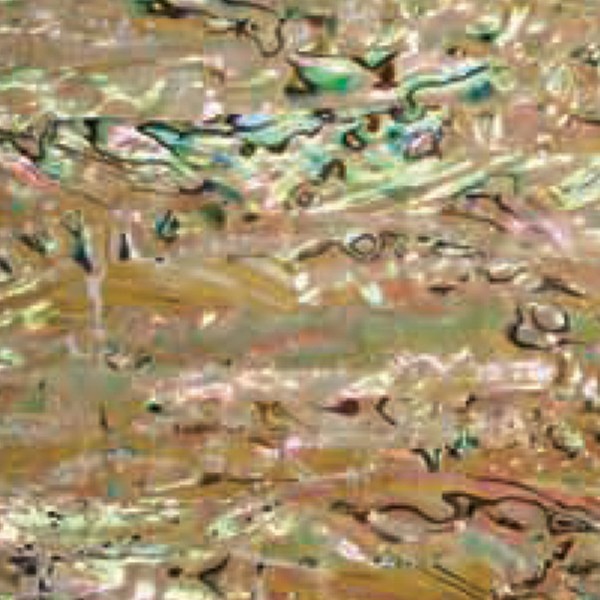

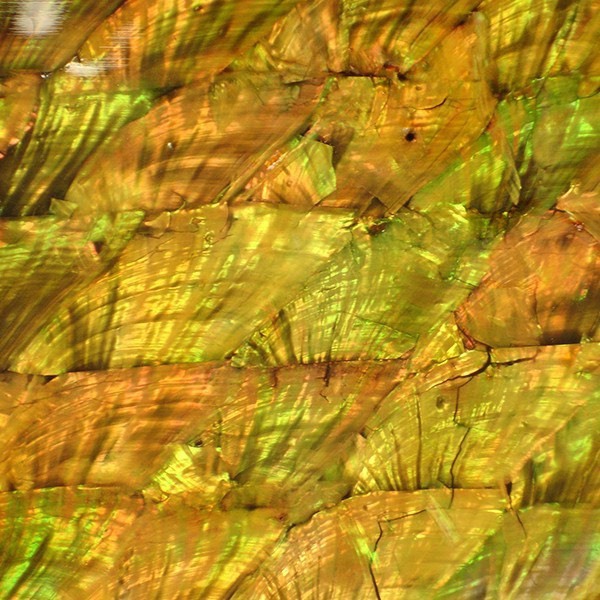

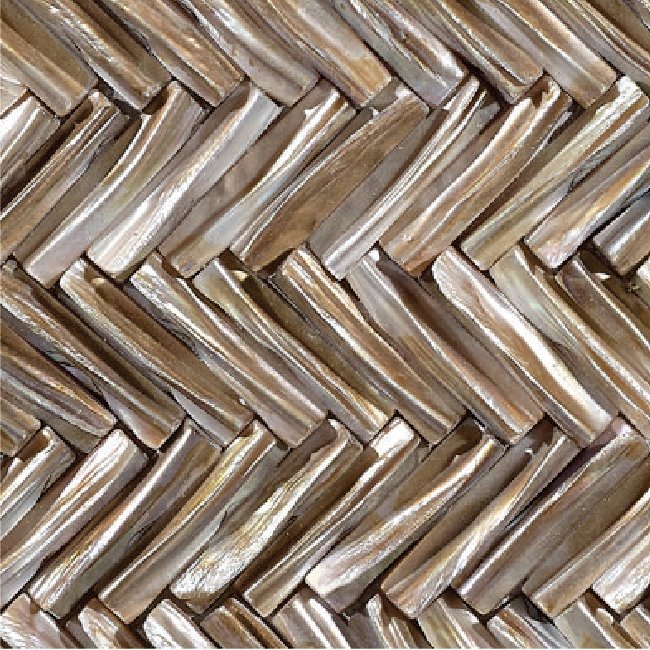

Genuine polished shell mosaic tiles are buff polished and hand applied butt joined (seamless) on various options of hard back surfaces.

Colors + Finishes

SeaTile Seamless tiles are available in authentic shell species colors they are polished shell and inlaid together in a number of patterns indicating the pattern style for the particular variety. Fresh water mother of pearl is a renewal shell and colors vary from little to no color shown as white or veined with colorations of the natural shell in hues of cream white to gold which is called “veined” from the color of the natural shell. The Beadz style are characterized by the placement of the pearl piece by piece on a translucent or hard back surface their coloration is a golden iridescent. The pearls sit proud on the face of the tile.

Natural shell colorations may vary from piece to piece which enhances the natural beauty of the product.

Sizes

SeaTile Standard Shell Panel 12” x 12” x 1/4” (300*300*6mm) Shell Mosaic size on panel: Square 1/2”x1/2” (15*15mm) or Brick Design 1/2” x 3/4” (15*25mm) other pattern designs shown below and all can be cut to various deco sizes. All sizes shown nominal. Other shell colors and or patterns are available by request.

Applications

SeaTile Seamless products offer limitless possibilities for use in design:

Vertical tile accents, Wall covering, Cabinetry Veneers, Lighting, Paneling, Yachts, Aircraft, Tour Buses.

Installation + Maintenance

Normal setting material suitable for ceramic tile if bisque backing is requested. Fire rated hard back may be installed with contact cement and typically requested for areas that are weight sensitive such as yachts or air craft. Products are recommended for interior vertical commercial or residential applications. Tiles may be installed in full sheets or cut to various sizes according to design application. Ceramic backing with minimal grout joints required for wet areas.

Use only non abrasive and non-corrosive cleaning agents such as soap and water.

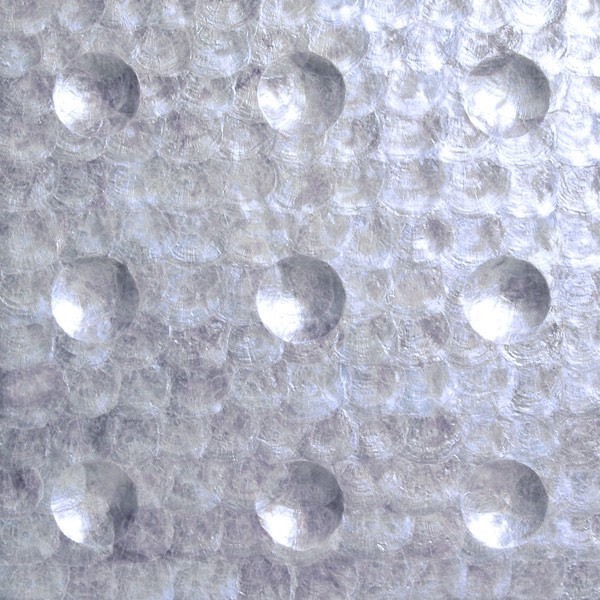

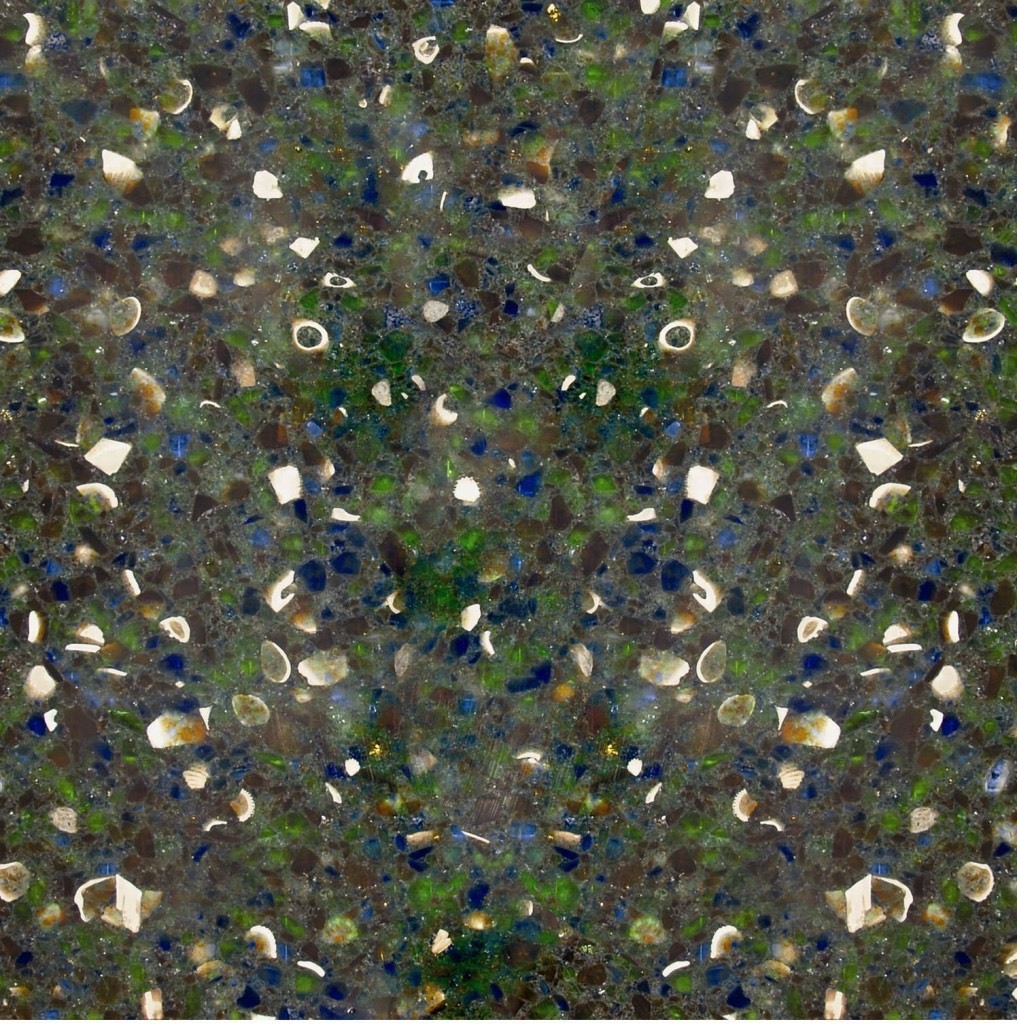

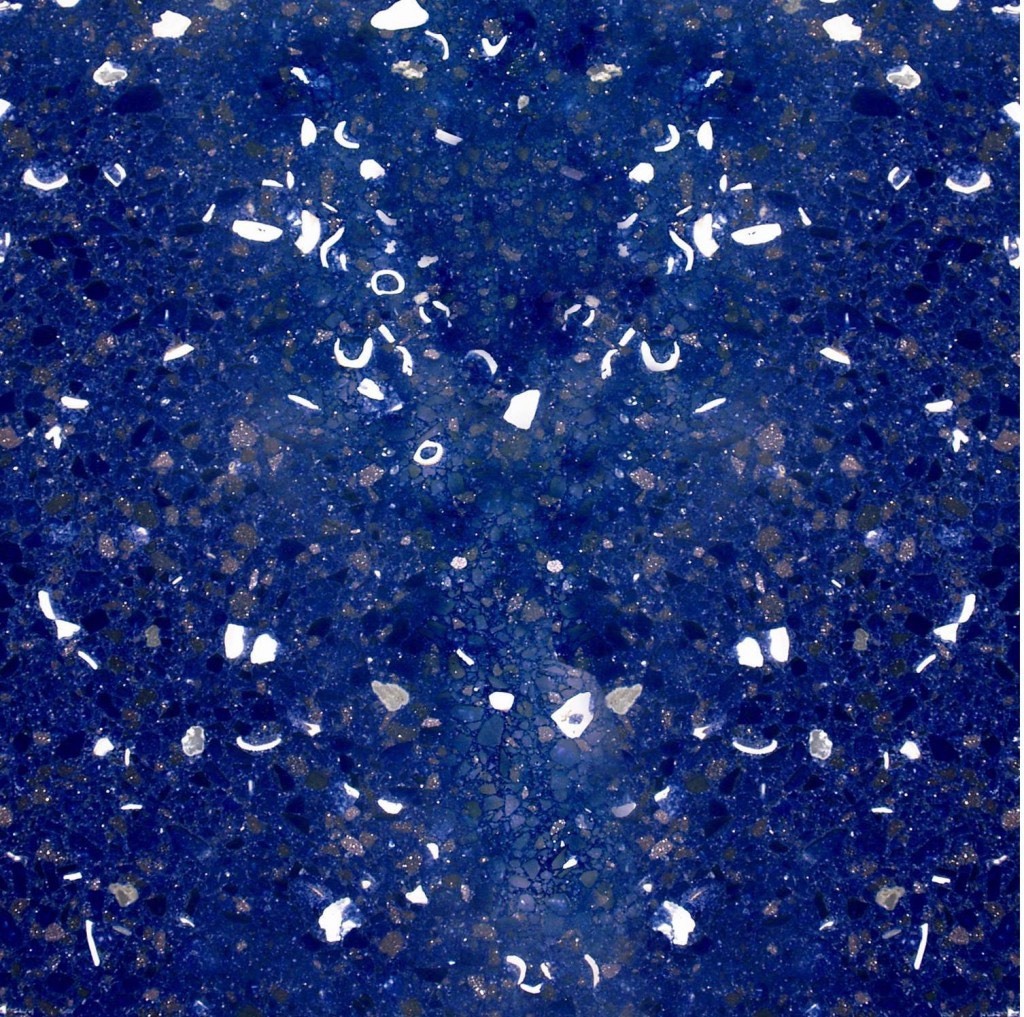

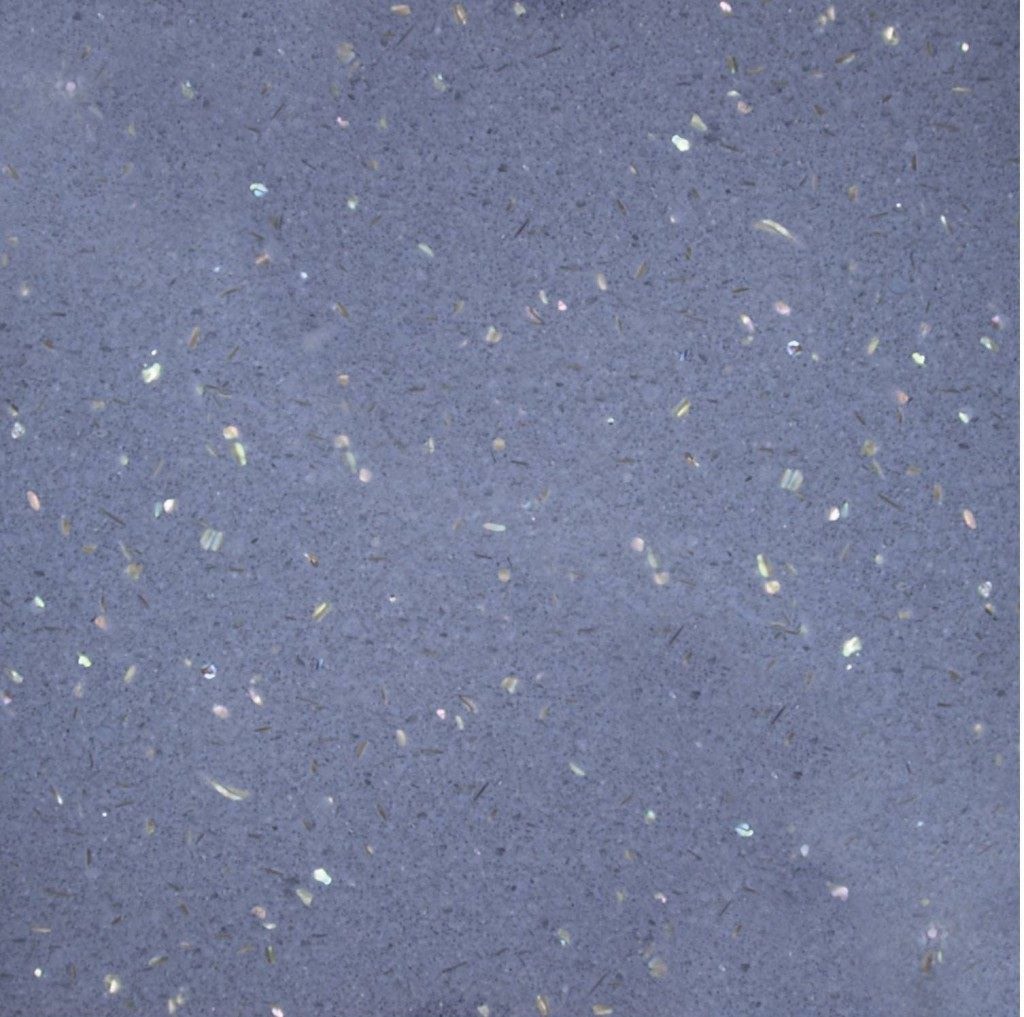

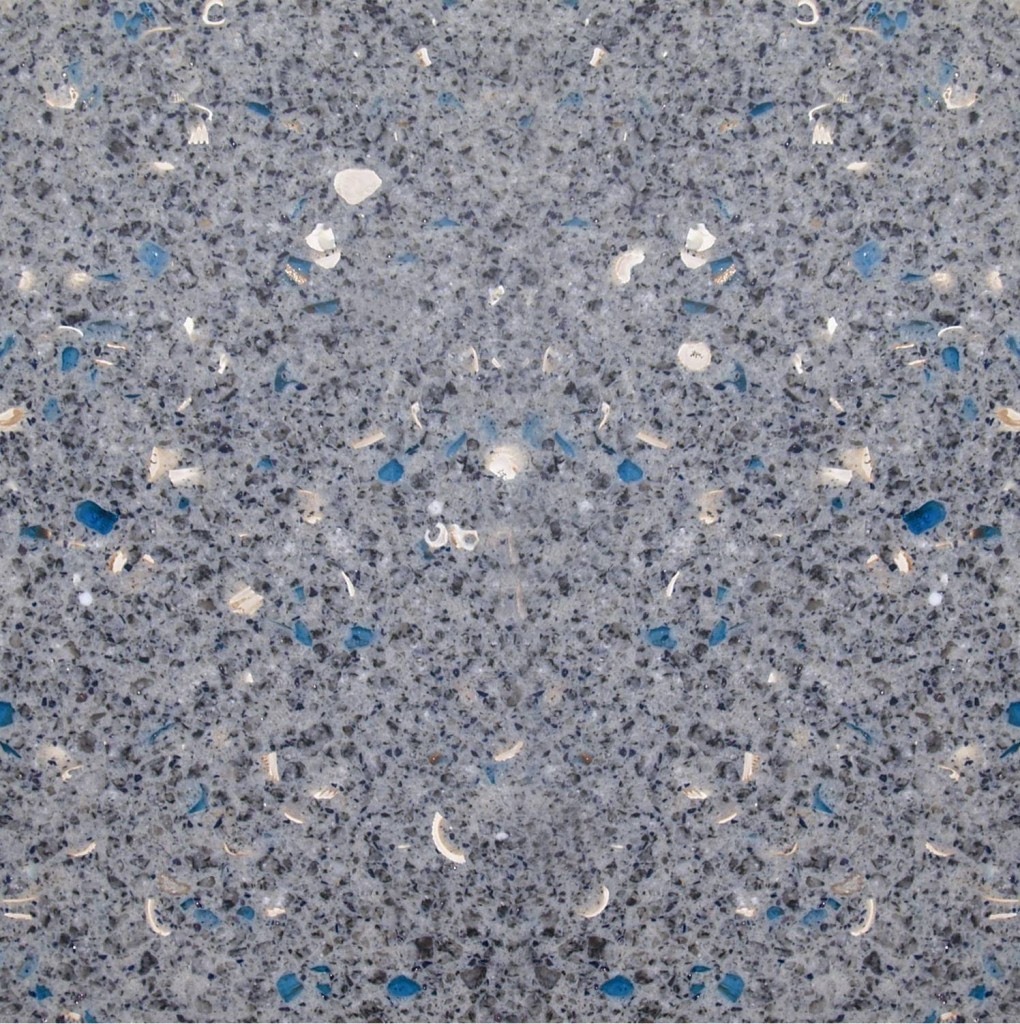

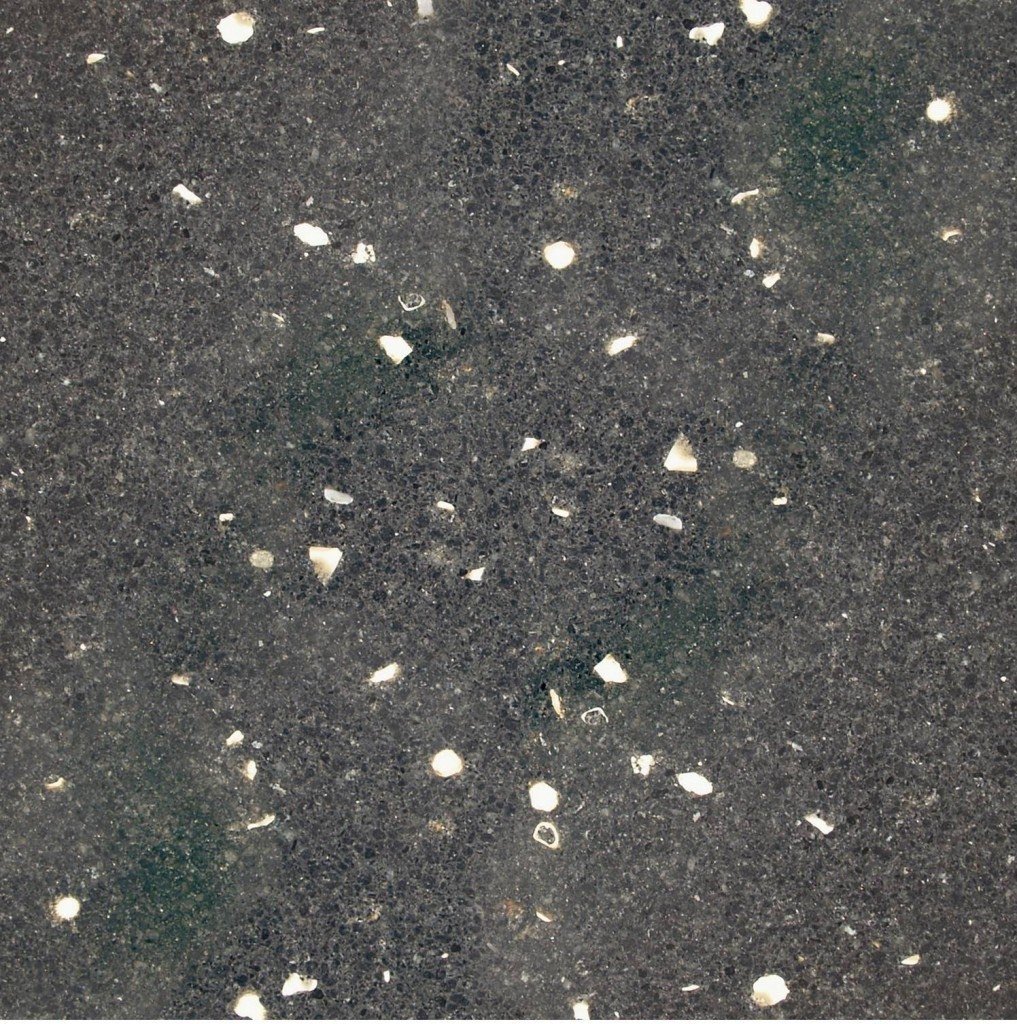

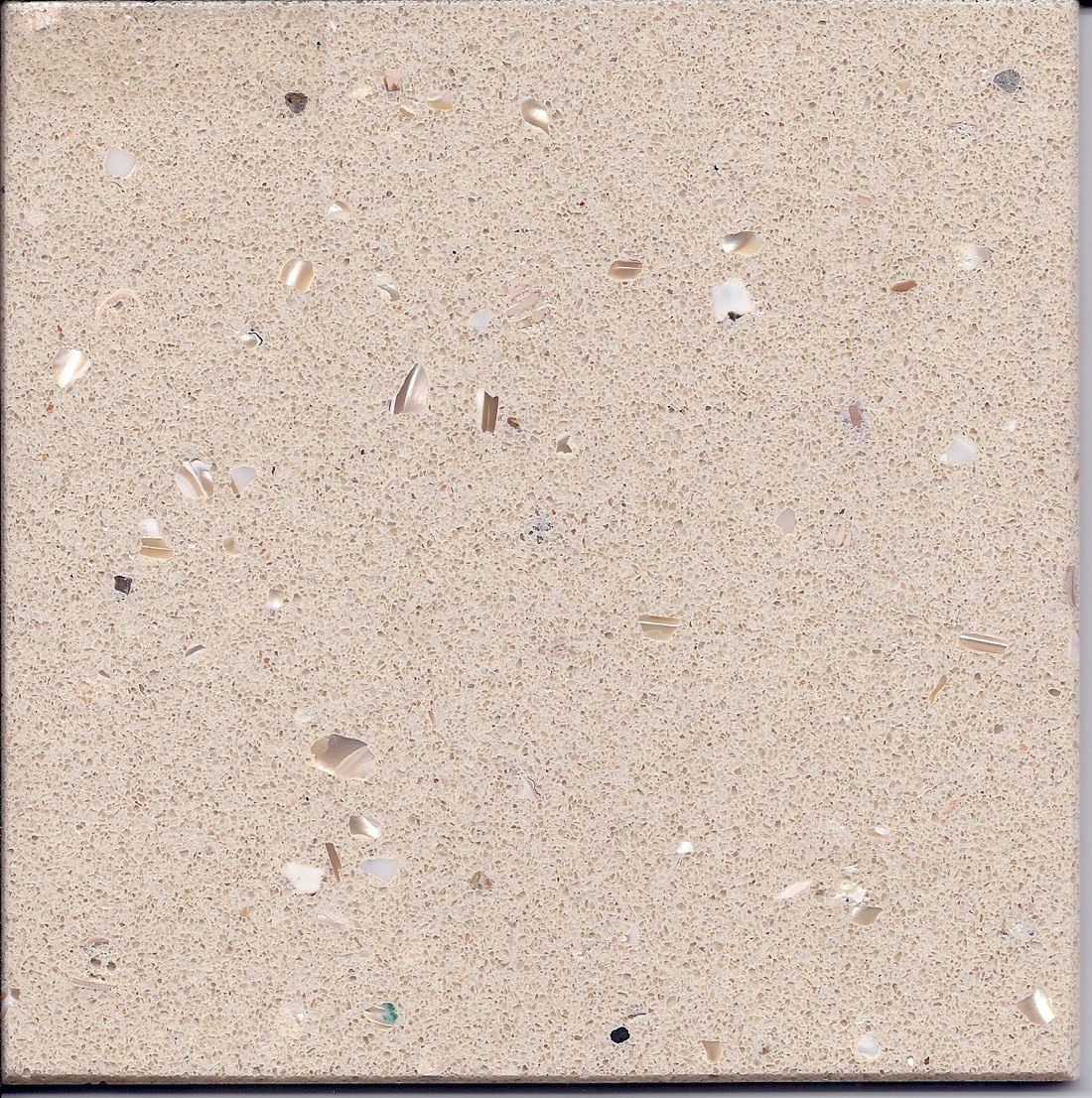

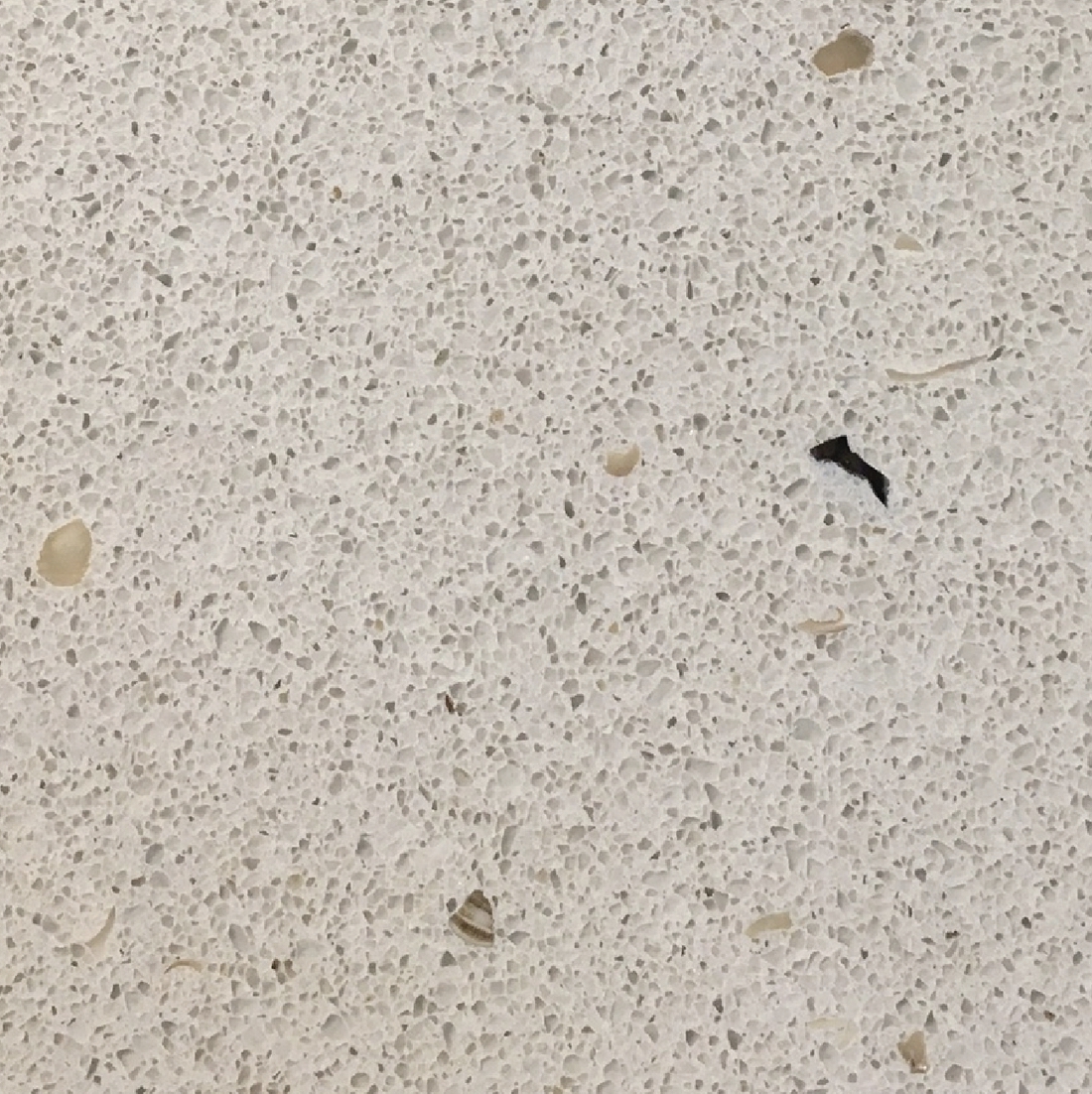

SeaTile Specialty Tile Gem Series

Gem Tiles & Slabs are a unique thin veneer composition. The tile is engineered to reveal a surface composition composed of natural shell, colored glass or other recycled elements for use in a number of interior and exterior applications. The Gem Series is available in exciting colorations and sizes up to 4’x10′ offering limitless possibilities for use in design. Products may be installed using standard mortar and grouts.

SeaTile Specialty Gem tiles are a unique thin veneer tile composition engineered to reveal a surface composition composed of natural shell, colored glass or other recycled elements for use in a number of interior and exterior applications.

Colors + Finishes

SeaTile Specialty Gem tiles come in 6 standard colors with options for with or without shell and in a standard gloss finish with or with out a micro bevel

Natural shell colorations may vary from piece to piece which enhances the natural beauty of the product.

Sizes

SeaTile Specialty Gem tiles are available in standard sizes 6”x 6”, 6”x 12”, 12”x 12” and 24”x 24” and slabs as large as 4’x10′ which can be used for counter tops and unique water features.

Applications

SeaTile products offer limitless possibilities for use in design:

Floor tiles, Vertical tiles, Pool Tile, water features & counter tops

Installation + Maintenance

SeaTile Specialty Gem tiles are installed using standard grouts and mortars.

• Install tiles carefully to avoid scratching with standard tile adhesives using white latex-modified thin set mortar for the bonding material andonly non-sanded grout with minimal joints. Installation should be performed by experienced installers, familiar with the methods and guidelines set forth by The American National Standards Institute (ANSI).

• Use only non-abrasive and non-corrosive cleaning agents such as soap and water.

• Load bearing waterproof membranes are recommended in wet locations such as baths and showers.

• After Care: wash down with warm water – spills of staining liquids such as wine, juice, coffee, etc. should be cleaned immediately with warmwater and liquid detergent.

All tiles should be installed in the same direction.

Curves or Radius Instructions:

(Thin Veneer Natural Shell Laminates Only)

• There is significant variation between shell types and strip versus mosaic sheets and their ability to bend or fit to a curved surface. All our sheets are capable of fitting to a 12” diameter circle or curve.

• Slightly bend the sheet one way, not around a curved surface going vertical and horizontally i.e. a ball.

• Laminates are more flexible if the grain or strips in the sheet are running horizontally around the curve.

• When gluing hold the sheets to the curve using either a good contact glue applied to both surfaces until sticky so that when the sheet is placed or pushed onto the surface it holds tight from the outset, or use double-sided tape provided the subsurface is suitable for the application of a double-sided tape.

Finishing: SeaTile® Ceramic Back and Laminate Natural Shell series are already coated with a special marine grade polyurethane so it is not necessary to recoat.Please consult with manufacturer if additional coatings are required.

SHELL IS A BRITTLE MATERIAL, CARE IN CUTTING IS REQUIRED. EXPERIMENT WITH A SMALL PIECE FIRST.

Cutting Instructions:

• CRAFT KNIFE SINGLE EDGE RAZOR BLADES: With a craft knife (tape first) score the laminate gently first, then progressively apply more pressureuntil cut is complete. To cut curves, draw shape on masking tape. Any rough edges can be lightly sanded.

• LASER: Shell Laminates come standard with a straight edge, however laser trimming is required for a seamless appearance. Laser cutting may be used forintricate designs and custom logos, which can be factory ordered (call for details).

All tiles should be installed in the same direction.

Gluing Instructions for product Without Self-Adhesive Backing:

• Preparation: Important if using acrylic backed laminate to ensure the back of laminate is finely sanded. Also sand surface receiving the laminate.Surfaces must be free of dust, oils, grease, and lubricants.

• To wood / MDF / metal / glass / acrylic: ENSURE COMPATIBILITY OF GLUE WITH SUBSTRATE MATERIAL * * READ LABEL * *Use Contact Adhesives, Epoxy Resin, or Double-sided Tape or ask for factory applied self-adhesive backing.

• To fiberglass: Use Polyester Resin

General Guidelines

• Inspect goods carefully. No returns on cut goods.

• Confirm that you have the correct color and product before installing. There are standard variation from batch to batch.

• Capiz sheets can display certain irregularities that are inherent to the manufacturing process.

• Product should be stored in a dry area, 60° – 85° F.

ACTIONS TO AVOID

• Do not crease Capiz sheets.

• Do not rub face of product with a stiff brush.

• Avoid direct or bright sunlight. Not guaranteed against fading or color change.

• Do not use in wet locations

Wall Preparation

• Paint the wall the color of the product with a good quality, non-sealing flat latex wall paint.

• Do not install on sealed walls without hanging lining paper.

• Walls must be completely dry before installation begins.

Trimming

• All tiles should be hung in the same direction.

• Trim with a very sharp, single edge razor blade. USE A NEW BLADE FOR EACH CUT. Experiment with a small piece first.

• Exposed edges should be installed using the factory edge. Create a template for tight corners or any surface that is not square.

• Trim this product from the back on a table, NOT on the wall.

Adhesive

• Use a good quality VINYL OVER VINYL, NON-STRIPPABLE adhesive.

• Apply a generous, even coat of adhesive to the product being careful at the edges so that adhesive does not get on the front of product.

• Allow to rest 5-7 minutes.

• WIPE OFF EXCESS IMMEDIATELY WITH A SOFT DAMP CLOTH. DRY WITH A CLEAN SOFT CLOTH.

Hanging

• Adhere product to the wall using a bristled nylon brush.

• Smooth product to the wall using a plastic smoother. Smooth continuously to remove any bubbles. Apply light pressure with a seam roller or linoleum roller foradditional adhesion.

Seams

• To reduce the appearance of seams we have found that a Brick method yields the best results. (See diagram below.)

• If gaps occur at the joints of tiles, use a latex caulk, approximately the color of the tiles. Any excess filler/caulk must be removed immediately. The area mustthen be washed down with soapy water to remove any residue. Please apply either of these products with EXTREME CARE. If not removed immediately, theycan damage the surface of the product.

• Slight irregularities on the edges can be remedied by lightly hand sanding the edges with a sanding block and 100 grit or finer sand paper.

Cleaning

• Wipe the area using a soft cloth and a very weak solution of a very mild liquid detergent.

• Dry with a soft cloth.

Recommended Installation Pattern

This is an acid free self-adhesive by product of natural shell. It has a strong adhesive with a white backing to peel off for placement. The shell laminate has a clear lacquer coating that can be sanded lightly and recoated. You can also sand any rough edges. This product is made from actual shell and therefore has certain fragility, so care should be taken when working with it.

Laminate Sizes: 12″x12″ / 5 -1/2 x 9-1/2 / 8″x8″ / 3″x6″ subway tile

Cutting:

Use either a craft knife or sharp scissors. With a craft knife score the laminate gently first, then progressively apply more pressure until cut is complete. For curves draw shape on masking tape. A laser can be used for intricate designs.

Punching and Die Cutting:

Simple shapes work best with shell laminate. If you place it carefully you can also use the outline shape in your work. Place the shell side away from the blade to reduce any shattering on edges.

Embossing, Stamping and Metallic pens:

You can emboss or stamp on the shell laminate. Metallic colors stand out best. With stamping and metallic pens, permanent inks generally work, but you may need to heat with an embossing gun to set.

Surface Preparation:

Laminate shell with or without adhesive backing will adhere well to prepared surfaces that are clean and smooth including acrylic painted surfaces.